Resources

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

In this article Microscopy Camera Specialist Dr Alan Mullan answers questions on the different types of camera sensor enclosures that are used for scientific cameras and how they affect camera performance and longevity.

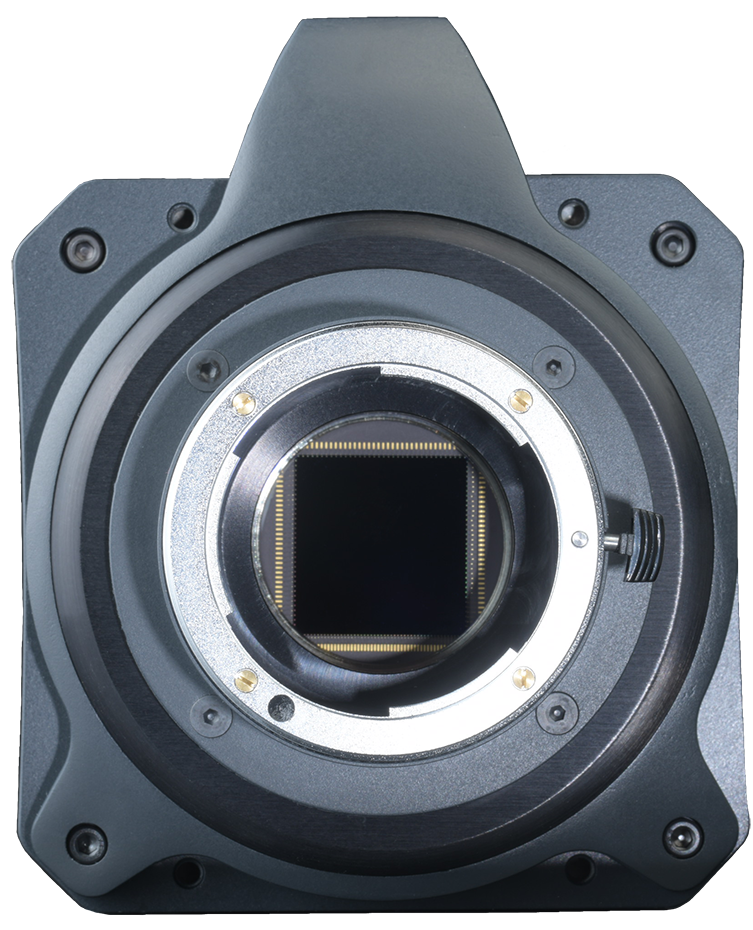

Figure 1: The Andor Sona camera features an UltraVacTM permanent vacuum seal for long term reliability and deep cooling.

The sensors used for scientific cameras are very delicate and easily damaged from physical handling and mechanical damage. In addition to, moisture, hydrocarbons or other gas borne contaminants all of which may degrade performance over time. For this reason, camera manufacturers need to protect the sensor from the external environment. For most cameras there is a camera window so that light may pass through to the sensor while dust and other contaminants may not. However, it is not easy to determine how the sensor is sealed within this enclosure or chamber and what the significance of this is to the performance of the camera and its longevity.

There are two main technologies which are generally used, “back-filled" and “vacuum”. Back-filled cameras are the most common type. This method can be found on small compact entry-level cameras through to the latest back-illuminated sCMOS cameras and other high-end scientific cameras. A vacuum sealed enclosure is a technically more difficult technology and therefore costly to implement so it is found less frequently. It is normally only found on higher performance cameras where long-term reliability and the highest sensitivity or deep cooling is required.

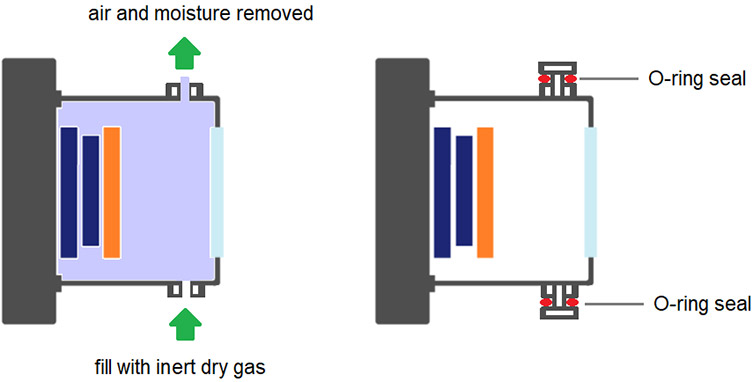

A back-filled enclosure refers to back-filling a sensor chamber with gas. Often the term backfilled may not be used and they will just be referred to as a “sealed” enclosure. The chamber of a back-filled camera is filled with an inert, dry gas such as Nitrogen or Argon. Once the air has been pumped out and replaced with a positive pressure of the gas used for “back-filling” the sensor chamber will be sealed up. O-ring seals are used to keep the gas in and the air, moisture and other contaminants out. This means you can avoid the moisture and other organic contaminants that would otherwise be present in the air from degrading sensor performance.

Figure 2: For back-filled cameras the sensor enclosure is evacuated and filled with a dry, inert gas and sealed using O-rings as summarized in this representative image.

Of the current Andor cameras portfolio, examples using a back-filled design would be the Andor ZL41 Cell and Wave sCMOS ranges. These use a robust back-filled design that offers higher longevity than other designs on the market. Our previous Zyla cameras that had a previous generation back-filled design can be fully upgraded to this new enhanced design.

A back filled camera does not operate under vacuum, the chamber is filled with an inert gas at normal pressure and the seal is via an O-ring. Over an extended period of time and depending on environmental and operating conditions, there will be a rate of ingress of moisture from the operating environment that will bypass the seal. Eventually, that can lead to condensation within the camera chamber on the camera window. With that said, the ZL41 cameras feature a robust chamber that provides an extended working life compared to other back-filled designs, with a MTBF (Mean Time Between Failure) of 10 years and a failure rate of only <0.05%. An iXon EMCCD with UltraVacTM with the permanent vacuum technology is the ultimate in longevity with a MTBF of over 100 years.

Moderate levels of cooling are possible from back-filled designed – the ZL41 Cell operates at 0 degrees C, keeping the thermal noise suppressed for typical short exposures of 50-500ms of fluorescence microscopy. To run longer exposures and deeper cooling, a vacuum and permanent seal is required. Andor’s Sona sCMOS and iXon EMCCD allow much deeper cooling of -45°C and -100°C due to exclusive permanent vacuum technology used in these designs.

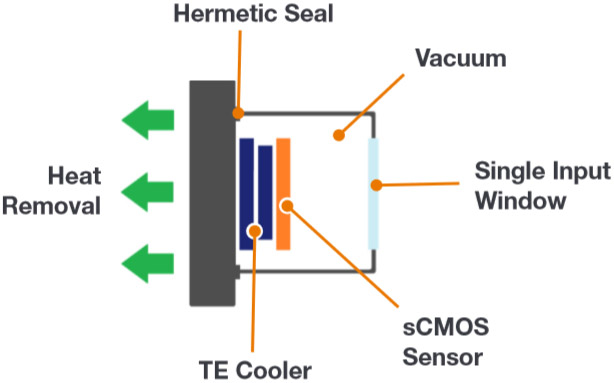

Figure 3: UltraVac™ – Andor’s proprietary permanent vacuum technology.

A vacuum enclosure provides the ultimate protection of the sensor over an extended service life. UltraVac™ is Andor’s proprietary permanent vacuum enclosure technology. UltraVac uses a permanent hermetic seal so there are no O-rings to leak. It has a proven reliability having been used on the Andor iXon EMCCD, Newton, iDus, iKon and the latest Sona and Marana back-illuminated sCMOS. UltraVac™ technology has been implemented in 1000s of Andor cameras over the last 20 years.

To find out more about UltraVac technology click here.

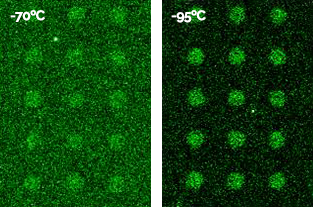

Figure 4: Deeper cooling of CCD models can help provide a reduction in dark current and drop the noise floor even between -70°C and -95°C. UltraVacTM ensures the deepest possible cooling and lowest noise floor of the sensor can be attained.

Aside from providing long-term protection of the sensor, a vacuum enclosure has a few other benefits. UltraVac™ enables deeper cooling which means that dark current can be reduced to the minimum for when longer exposures are required.

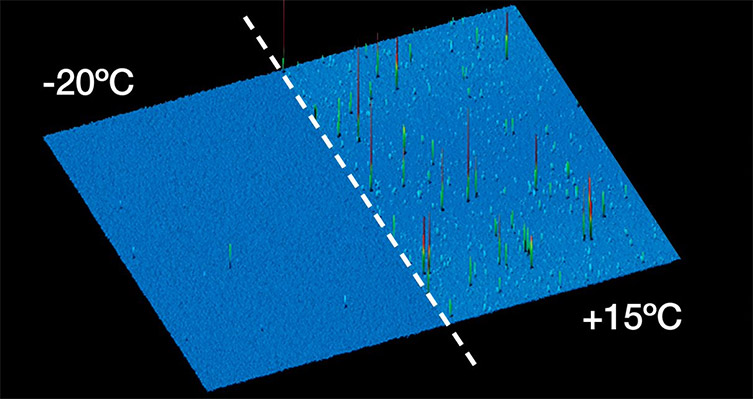

Hot pixels and other pixel blemishes are also reduced when the sensor is cooled meaning that the overall image quality can be improved. This can be particularly relevant to sCMOS cameras due to the higher pixel to pixel variation that these cameras have compared to CCD.

Figure 5: Cooling of sCMOS sensors can reduce dark current as well a¬s reduce the impact of blemishes

Vacuum technology requires production facilities, equipment and complex processes to implement it in a camera which means the associated costs are higher than for back-filled enclosures. However, the UltraVac™ process is a key part of many of our camera platforms at Andor so the cost of this is minimized through the volume of cameras we produce with this process.

Cameras that use UltraVac™ technology include iXon Ultra and Life, iKon series (iKon-M, iKon-L and iKon-XL), Newton, Idus, iVac and Neo. The new back-illuminated sCMOS Sona and Marana models also feature UltraVac™ technology. Some variants of these cameras are used for high energy applications and may be open fronted so, in these cases, cameras may be mounted to a vacuum chamber directly.

Sensors generate heat during operation which we would see as dark current and a high noise floor if it is not removed. So, a cooling system is needed to remove this heat, which becomes more important for low light applications and longer exposure times. For most scientific cameras the sensor will be coupled to a thermoelectric cooler or a passive cooler assembly for compact designs. Therefore, heat from the sensor can be removed from the camera via air cooling using a fan or water cooling using a water chiller. The sensor also needs wires passing through to the electronics boards on the other side of the sensor enclosure so that the signals from the sensor itself can go for amplification or processing so that an image can be displayed. The camera window is also important as this will have its own transmission efficiency profile. The camera window will be selected for optimal transmission efficiency to suit both the sensor and the application that the camera will be used for. To find out more about camera windows click here.

The camera backfill or vacuum will have a warranty period which will cover any failure within this time. The warranty period of the camera seals is specified separately to the rest of the camera. If the you encounter condensation or any other failure outside of the warranty period the camera will need to be serviced, at cost to the customer. It is therefore important to be aware of this and that this is a normal part of the life of any camera.

Customer support information including warranty information for both back-filled and vacuum sensor enclosure technology cameras is available at https://andor.oxinst.com/support/