Resources

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Laser produced plasmas are being used to deposit thin films of exotic materials with well controlled stoichiometry and crystalline properties such as ferromagnetics, ferroelectrics and high temperature superconductors. Key to the optimisation of growth of such films is the understanding of the fundamental processes which occur in the plasma plume from the time of the initial laser interaction with the target, the evolution of the plasma plume and the deposition and growth of the ablated material on to the substrate. Intensified ICCD cameras are an invaluable tool for the analysis of the evolving species within the plume. This note outlines how a group at the Paul Scherer Institute, Switzerland, working on multiferroic materials, are using an ICCD (Andor-iStar) to image such plasmas in time integrated and time resolved studies.

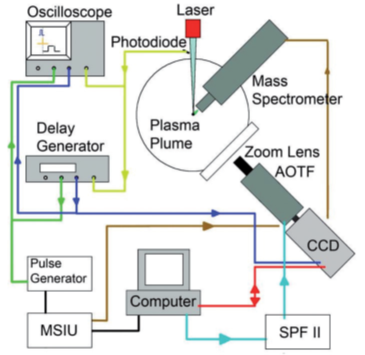

Figure 1: A top view of the UHV chamber with target in the centre. The pulsed laser beam generates a plasma plume that is directed towards the mass spectrometer. A window perpendicular to the plasma expansion allows for investigation by optical methods. A lens system images the plasma through the acousto-optical tuneable filter onto a high-speed ICCD.

Multiferroics are materials which exhibit simultaneously in the same phase several of the ferroic properties such as ferromagnetism, ferroelectricity and ferroelasticity. They are very promising systems for future applications in computing or sensing. These materials could allow for the design of new digital storage devices that combine the advantages of long lived magnetic storage with the easy accessibility and robustness of electronic storage technology. However, such materials which combine these properties are scarce.

For many applications it is desirable to produce these materials in the form of thin films. Whilst this poses its own challenges, thin film growth introduces new parameters such as strain which can allow for tuning of the material properties, and consequently to better adaptation of the multiferroics to particular applications. To aid in the controlled and targeted growth of these materials, the group use optical emission spectroscopy and time resolved imaging to investigate the plasma during pulsed laser deposition (PLD) process.

Pulsed laser deposition (PLD) is a very powerful technique to evaporate materials (metals or ceramics) in a vacuum or a background atmosphere through the creation of a plasma. The species from this plasma cloud condense on a substrate where the growth of a thin film takes place. PLD was used to grow the thin films used in this study. A promising multiferroic material, LuMnO3 (Lutetium Manganese Oxide), has an orthorhombic crystalline structure. However its orthorhombic structure is metastable and consequebtly it is not easy to synthesize it in bulk form for the study of its electrical and magnetic properties. Preparing it as a thin film is one way to obtain high quality stable material with the correct crystalline structure, although this is not easy to accomplish.

Several Lu-containing targets were used to investigate the PLD deposition of LuMnO3, with particular focus on the properties of the Lu plasma species. The Lu-containing targets studied included: i) a metal Lu disc target, ii) a ceramic Lu2O3 disc target, and iii) a cylindrical ceramic target of hexagonal-LuMnO3. A KrF excimer laser operating at wavelength of 248 nm was used at a repetition rate of 8 Hz with a laser fluence of ~3.5 J/cm² was used to ablate the targets. The laser beam was focused to a spot size of ~1.7 mm² with the use of an imaged 9 x 9 mm² mask. The background pressure was varied from vacuum (1 x 10-8 mbar) to 1.5 x 10-3 and 5 x 10-2 mbar using N2O and O2 background gases.

Plasma imaging was performed using Andor Solis software and a USB ICCD camera (iStar DH334T-18F-03) coupled to an acousto-optical tuneable filter or AOTF (Brimrose VA210-.40-0.65 H) operating in the wavelength range of 400 - 650 nm. The wavelength resolution possible was ~0.8 nm for the shorter wavelengths, and up to ~2.1 nm at 650 nm. The specific camera settings for gating, frame repetition rate and delay times are given in the relevant parts of the discussion below. In order to image the entire plasma (4 cm long), including the target and the mass spectrometer nozzle, a Nikkor (28 - 300 mm) lens was used. It was placed at a distance of 550 mm from the plasma and set with ~200 mm focal length.

The time and space resolved optical emission measurements were complemented with mass spectroscopy measurements to determine the plasma composition or species and the respective kinetic energies of these species. Both, the mass spectrometry and the plasma imaging were triggered from the same fast photodiode placed in the laser beam path which ensured accurate synchronisation of the measurements (see figure 1). The emitted plasma radiation was measured as a function of time, space and wavelength. Changes in relative intensities between Lu and LuO lines over time showed distinctly different behaviour when comparing vacuum conditions with those in an oxidizing background gas. While the initial expansion of plasma species for all background conditions was similar, the behaviour changed at later times when the interaction between species from the target and the background gas become dominant. In an oxidizing background gas the relative intensities increased favouring the oxidized species which agrees well with observations from mass spectrometry.

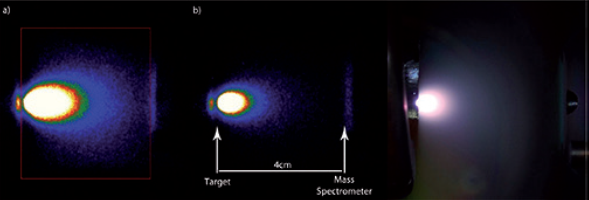

For the plasma imaging, the entire plasma was pictured with a specific filter in place that selected a narrow wavelength bandpass, ideally a single wavelength. A gate width of 10 μs was used to capture the integrated intensity over the time the plasma existed. The emissions from the Lu target at 499 nm (from Lu I species) and 518.5 nm (from the LuO species are shown in figure 2 (a) and (b) respectively. These are compared to an optical photograph shown on the right of the figure (c). With this data the integrated spatial expansion of these species could be studied. Whereas the excited Lu species seemed to reach the mass spectrometer (and corresponding substrate position), the intensity for excited LuO species was severely diminished at this position. This was confirmed by the mass spectrometry measurements where the numbers of LuO arriving at the substrate position was ~100 times smaller than for Lu.

Figure 2: a) Lu I emission at 499 nm. The red square shows the area over which the intensities were integrated. b) Emission from a LuO line at 518.5 nm. c) Broadband optical photograph of the plasma. All images correspond to the same fluence of 3.5 J/cm2 on target in the vacuum chamber.

Nitrous oxide (N2O) was introduced as a reactive background gas to enhance the creation of the metal oxide species needed to form orthorhombic LuMnO3; these species are formed due to the chemical reactions taking place in the plasma cloud. The increase in the number of metal oxide species was observed as a function of the background pressure.

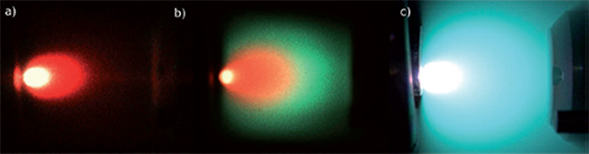

It was observed that the distribution of excited Lu and LuO species in the plasma at a pressure of 5x10-2 mbar in the N2O background, was very different compared to that observed in vacuum. The distribution of the excited Lu I species is shown in figure 3(a) (in red) where a significant fall-off in its intensity is already evident halfway between the target and the mass spectrometer position (in consideration of the plasma plume expansion). In contrast the emission from the excited LuO species is evidently stronger with increasing distance from the target as shown in figure 3(b) (green). This is due to the much reduced mean free path of the plasma species at this pressure resulting in increased collisions. This leads to increased chemical activity and the creation of more LuO species further away from the target. These collisions also contribute to a re-excitation of LuO and thereby enhance the effective lifetime of these excited species; this is observed as a half-moon shaped distribution around the area associated with the Lu I species (see figure 3(b)). A comparison of the extent of the LuO cloud in figure 3(b) with the extent of the plasma in the optical image of 3(c), shows that the areas coincide reasonably well.

Figure 3: Overlays of false-coloured images for Lu I (red) and LuO (blue/green) in different backgrounds: a) in vacuum and b) in 5x10-2 mbar N2O gas. (intensity is a factor of x10 larger in (b) compared to (a)). c) an optical photograph of the plasma plume in 5x10-2 mbar N2O gas.

Further information about the processes taking place inside the plasma can be gained by time-resolved measurements. A series of measurements were taken with the gatewidth reduced to 50 ns and the gate delay varied between frames in 90 ns steps, with a total of 30 frames being acquired; each individual frame in the series consisted of 50 repeated shots integrated on chip (IOC). A selection of frames for the different species, taken from different acquisitions for three different background gas conditions, are shown in figure 4. The images compare Lu I and LuO for each of three backgrounds, top of figure is for ‘in vacuum’, middle is for N2O with pressure of 1.5x10-3 mbar, and bottom is for N2O with pressure of 5x10-2 mbar. The intensity with the higher pressure gas was much larger than the other two so for comparison purposes the scales for the top and middle images were scaled up by a factor of x10. The bright horizontal line in the top images of each set was due to internal reflections of the lens (reference the lens-flare effect for bright point light sources).

Figure 4: Plasma images for Lu I (top row of each block) and LuO (bottom row of each block) at different delay times for three different background conditions: a) vacuum, b) 1.5 x 10-3 mbar N2O, and c) 5 x 10-2 mbar N2O. All measurements performed on the Lu target.

As evidenced in the images the behaviour changed dramatically with the increase in background pressure from vacuum to 1.5x10-3 mbar and then to 5x10-2 mbar. In vacuum the intensity of the Lu I emission is stronger than the LuO intensity during the whole ablation process as would be expected from the deficiency in oxygen. The LuO emission becomes similar in intensity to Lu I for the intermediate pressure and is even stronger than the Lu I emission very late in the process. A significant change happens in the highest pressure case where the LuO intensity surpasses the Lu I emission after ~1000 ns. The difference further increases for later stages of the plasma expansion process. In particular for later times the plasma species move with a common speed in a so-called shockwave where most of the interaction with the background gas, and therefore the oxidation takes place.

Integrating the intensities for the data of figure 4 shows that from vacuum to the intermediate pressure, an increase of the intensities for both Lu I and LuO is observed with a small increase in the LuO/Lu I ratios. At the highest pressure a strong increase of the LuO intensities is observed after ~400 ns, with a maximum occurring at around 1200 –1300 ns at which time the plasma reaches the mass spectrometer; this is consistent with the observed distribution of species in the plasma. At the highest pressure, the oxidation at the shockwave becomes the dominant process and leads to a strong oxidation of the metal Lu species to LuO and higher oxides, as confirmed by mass spectrometry.

The group demonstrate the highly successful use of mass spectrometry and plasma imaging in characterising plasma plumes used in pulsed laser deposition of various materials. Specifically for this data they show that the majority of LuO species is created within the plasma where the Lu I species interacts with the background N2O gas particularly in the region of the shock front. The iStar ICCD camera combined with an acousto-optical filter enabled the acquisition of plasma images of the different species of interest with a range of time delays and resolutions.

The information and figures for this note have been gratefully received from Dr CW Schneider, and his colleagues Dr M Bator and Dr T Lippert, of the Department General Energy, Villigen PSI, Switzerland

Date: May 2013

Author: Andor

Category: Application Note