Resources

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Modern security and surveillance technology is relied upon to deliver increasingly accurate situational awareness while remaining dynamic and autonomously adaptable in the field. As a result, airborne surveillance platforms, including both crewed aircraft and unmanned aerial vehicles (UAVs or drones), have become indispensable in meeting many security challenges. This article outlines the advantages provided to airborne surveillance by Short-Wave Infrared (SWIR) imaging systems and describes the attributes that must be considered when selecting a camera for this application.

Imaging at SWIR wavelengths (0.8-2.5 µm) offers significant advantages over imaging at visible wavelengths in surveillance applications. Because SWIR photons penetrate much further through air than visible photons before being absorbed or scattered, SWIR imaging systems can clearly image targets at increased range (Wiley et al. 2022).

Figure 1 - The electromagnetic spectrum showing the Ultraviolet (UV), Visible, Short Wave Infrared (SWIR), and Mid/Long Wave Infrared MWIR/LWIR wavelength regions.

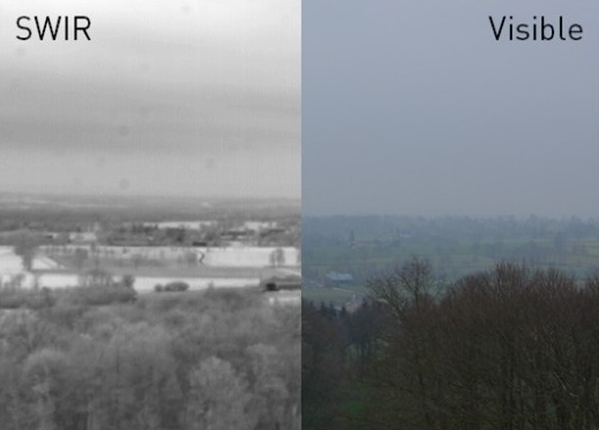

For airborne surveillance this means that accurate SWIR imaging can be achieved over a larger range of distances from (or altitudes above) a target on the ground. The increased range afforded by SWIR imaging is shown in Figure 2.

Figure 2 - Demonstration of the increased range achieved by imaging at SWIR wavelengths instead of visible wavelengths. In this image SWIR light also cuts through the fog to image the countryside at much greater distances. An uncooled C-RED 3 camera combined with a 16 mm SWIR lens was used to capture the SWIR image.

While atmospheric conditions such as fog, haze, dust, or smoke reduce visibility at visible wavelengths they are effectively transparent in multiple bands of the SWIR spectrum. SWIR imaging systems are therefore readily adaptable to use in a wide range of real-world conditions without technical intervention or reconfiguration. Figure 3 demonstrates the ability of SWIR imaging to detect what otherwise might be obscured by the elements.

Figure 3 - Haze across the Potomac River in visible light (left) and in SWIR (right; Driggers et al. 2013). Images courtesy of Peter Judd and James Waterman, NRL.

Many materials reflect and absorb light more distinctly at SWIR wavelengths than they do in the visible range. The enhanced contrast between different materials in SWIR images often makes it much easier to discriminate objects with different construction or composition. For example, figures 2-4 all demonstrate how SWIR imaging starkly reveals the contrast between artificial structures and their surrounding environment. Different materials comprising these buildings, like glass, concrete, and metal are also readily identifiable. Likewise, it’s even possible to both distinguish different types or species of vegetation and to separate the trunks of trees from the canopy. This ability to firmly discriminate and characterise objects aids rapid accumulation of detailed situational awareness that supports well-informed decision making, strategic planning, and accurate identification of threats.

Figure 4 - An uncooled C-RED 3 camera with a 70-200 mm tele-objective is used for a surveillance application.

Accurate SWIR surveillance imaging from a drone requires a sensitive, reliable, high-speed, low latency SWIR camera with minimal size, weight, and power consumption (SWaP). Some degree of autonomous operation is often also desirable.

Andor recommends the C-RED 3 for drone-mounted SWIR imaging. C-RED 3 is a compact, uncooled, high-speed SWIR VGA camera that incorporates the 640 x 512 InGaAs Snake SW sensor from Lynred. Let’s break down this camera’s attributes (also see Table 1):

| Property | Result | Unit |

| Full frame maximum frame rate | 602 | FPS |

| Mean dark + readout noise at 600 FPS | <50 | e- |

| Quantization [HDR Mode] | 14 [16] | Bit |

| Quantum efficiency at 1.00-1.65 µm | >65 | % |

| Operability | >99.7 | % |

| Low gain full well capacity, 600 FPS | 1400 | ke- |

| High gain full well capacity, 600 FPS | 33 | ke- |

| Power consumption | 6.5 | W |

| Dimensions | 56 x 56 x 59.5 | mm |

| Mass [OEM Mass] | 0.23 [0.1] | kg |

| Minimum operating temperature | -40 | C |

| Maximum operating temperature | +35 | C |

Table 1 - Relevant measurements of C-RED 3’s performance and properties.

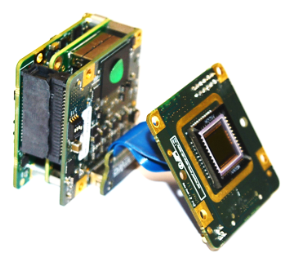

C-RED 3’s compact low SWaP design simplifies its integration into a larger system. Multiple options are provided for operational, optical, software, and data integration for C-RED 3. (see Table 2). Mechanical integration flexibility can be further enhanced in the camera’s OEM (without housing) format, and we can work with customers to deliver custom formats that precisely match their needs. The electronic boards of the sensor can be located several centimeters from the stack.

Figure 5 - C-RED 3 camera in standard housed (left) and OEM (right) formats.

| Operation Platforms | Windows® 11, Linux® Ubuntu 16.04 LTS & 18.04 LTS, and also on NVDIA® Jetson Tx2, Xavier NX and Nano |

| Data Interfaces | USB 3.1 and Camera Link (Full) |

| Optical Interfaces | C-Mount/CS-Mount |

| Software Interfaces | First Light Vision software, FLI Software Development Kit (MatLab, LabView, C/C++, Python, etc.) |

Table 2 - Interface Options for C-RED 3.

Figure 6 - Example of a C-RED 3 camera in a custom format.

1. Driggers et al. 2013, Proc. SPIE 8706, Infrared Imaging Systems: Design, Analysis, Modeling and Testing XXIV, 87060L

2. Wiley et al. 2022, Proc. SPIE 12106, Infrared Imaging Systems: Design, Analysis, Modeling, and Testing XXXIII, 1210606

Date: August 2025

Author: Tom Seccull

Category: Solution Note