Resources

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

C-RED 3 is a 640 x 512 SWIR camera running at 600 FPS full frame. Developed specifically for industrial applications, it combines high performances with low SWaP (size, weight, power consumption) and low price features. This article highlights the use of C-RED 3 for non-contact monitoring of weld deposition. The spatial and temporal resolution of the imaging system are highlighted in two use cases: Wire Arc Additive Manufacturing and Manual Metal Arc Welding.

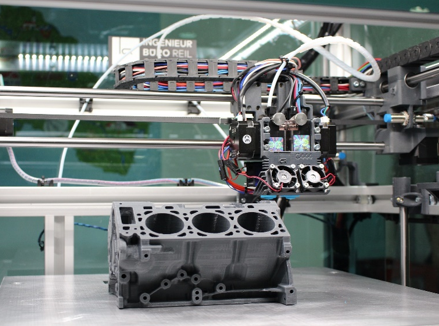

Additive manufacturing refers to a process in which a piece is built up by depositing a material layer by layer according to a 3D plan. This technique is widely used in the automotive and aerospace industries.

Metal additive manufacturing techniques include: Wire Arc Welding, Powder Bed Fusion, Fused Filament Fabrication, Laser Metal Deposition, etc. In all processes, it is crucial to control the pool of molten material, where the welding reaction occurs. Its geometry and temperature during the process will influence the final properties of the weld (resistance, structure, residual stress, etc.).

Progress in camera technology has allowed manufacturers to rely on non-contact monitoring of the additive process. This has the advantage of removing operators from a hazardous environment and providing real-time reliable information on the welding process: alignment of the welding tip, proper formation of the weld pool, etc.

For imaging, the SWIR range (900 – 1700 nm) offers multiple advantages over visible (400 – 750 nm). Particular properties such as the ability to see through some materials can be exploited. The weld pool and hot solidified melt are clearly visible in SWIR while plasma and metal vapor are not. Additionally, thermal measurements from SWIR images are precise in the temperature range at stake (300°C – 5000°C). The user will be able to assess the homogeneity and control the heat profile of the weld pool during the process. Finally, in processes where the power source is a laser, the wavelength is selected to be at the maximum absorption of the metal. For metals such as iron and copper the laser is usually a YAG laser at 1064 nm, falling within the SWIR range.

A very high dynamic range is required to acquire the information at both the low brightness (cooled weld in the background) and high brightness (weld pool, laser, etc.) zones, without saturating. A high-speed scanning rate is necessary to study the physical process of very fast energy transfer from the heat source to the material and within the material.

The C-RED 3 camera is a good candidate for welding monitoring. We will illustrate the use of C-RED 3 in two experimental arc welding use cases to demonstrate its performances.

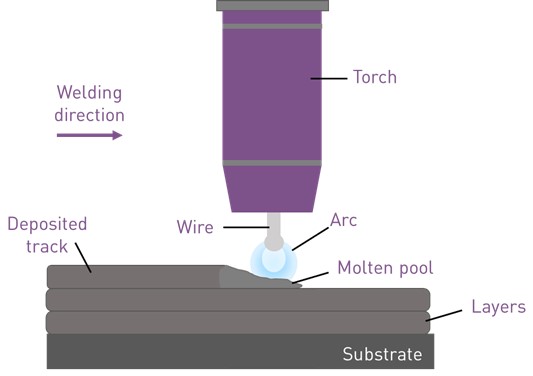

WAAM is a type of directed energy deposition process in which a metal wire is supplied at a controlled rate into the welding arc. The metal wire is completely melted and the previously deposited layer is melted partially to enable the material growth. The output of the process is a fully dense part [1].

As the printing process includes high temperatures, there can be residual stress in the piece, leading to some distortion. One of the challenges of WAAM is to manage the temperature of the weld during material deposition and cooling.

Research is still on-going to optimize the parameters of the welding process (temperature, material thickness, etc.). Monitoring the weld pool and studying the post-deposition heat distribution is one research subject.

WAAM working principle

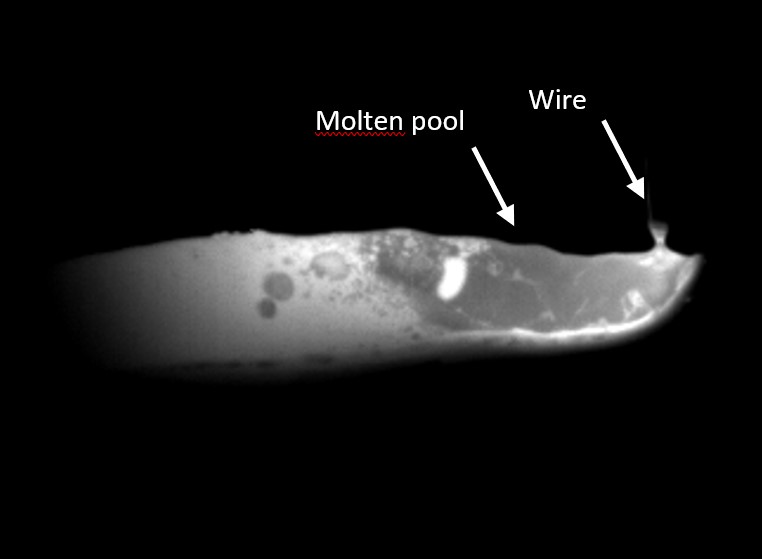

The C-RED 3 camera combined to a 50 mm objective lens was used in a welding monitoring experiment to study the molten metal dynamics within the weld pool.

The acquisitions were made with the Low gain capacitor at maximum framerate (600 Hz) and an ultra-short exposure time of 1 µs integration time (available with short tuning optimization). The full SWIR band was imaged, without spectral filtering

The very high spatial resolution enables to capture details of the weld pool, such as small inclusions. The high temporal resolution allows to follow movements within the weld pool during the additive process.

The wire metal is completely melted to be deposited on the weld pool.

Watch the video on our YouTube channel: “Application : Wire Arc Additive Manufacturing”

An electric arc is used as the power source to melt the metal wire. The homogeneity of the weld can be assessed in real-time.

First Light Imaging acknowledges Photon Lines and the LMGC laboratory for performing the WAAM imaging.

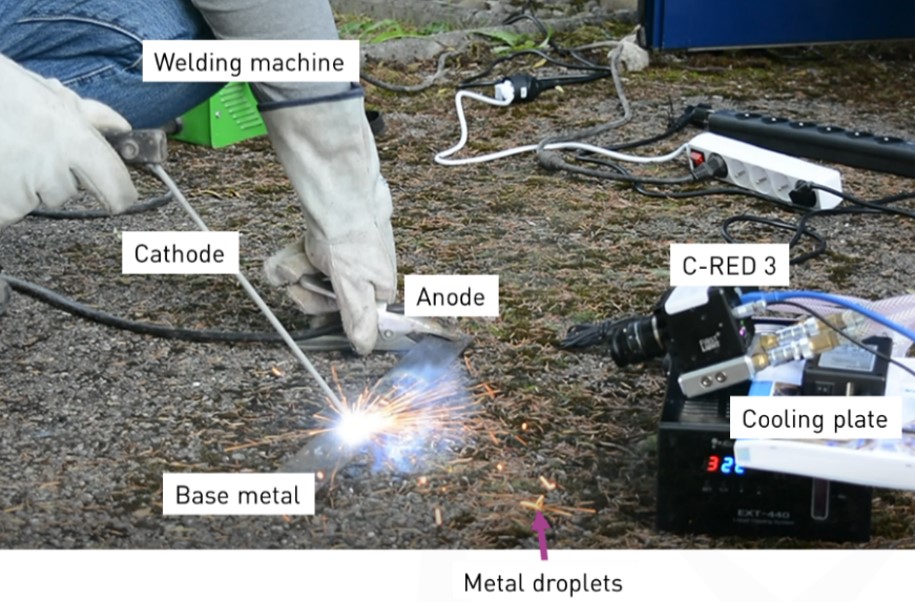

Manual metal arc welding is another process in which an electric arc is used as the heat source to melt metal. The welding machine provides electricity to create an arc between an electrode (cathode) and the base material at a contact point [2]. Imaging during such a welding process is challenging, as the environment is harsh (high temperature, smoke, and dust). Due to important temperature gradients within the scene, the camera must handle simultaneously very high illuminations and contrasts.

Set-up for the welding experiment.

A calibrated imaging system based on a C-RED 3 camera was used to record a video of a manual welding experiment. The High Dynamic Range (HDR) mode at 600 Hz (integration time 50 µs) was used to perform a real-time monitoring of the apparent temperature of the weld.

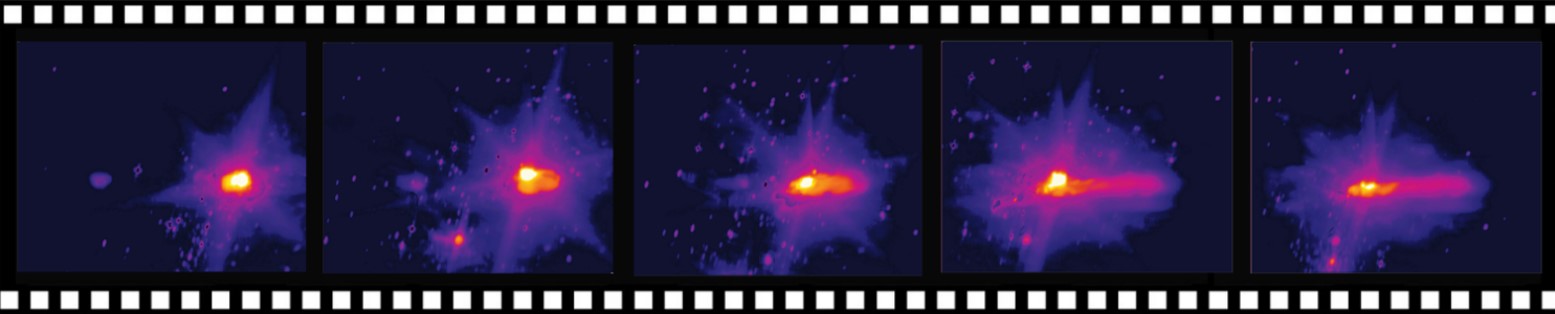

Time-lapse of the welding process.

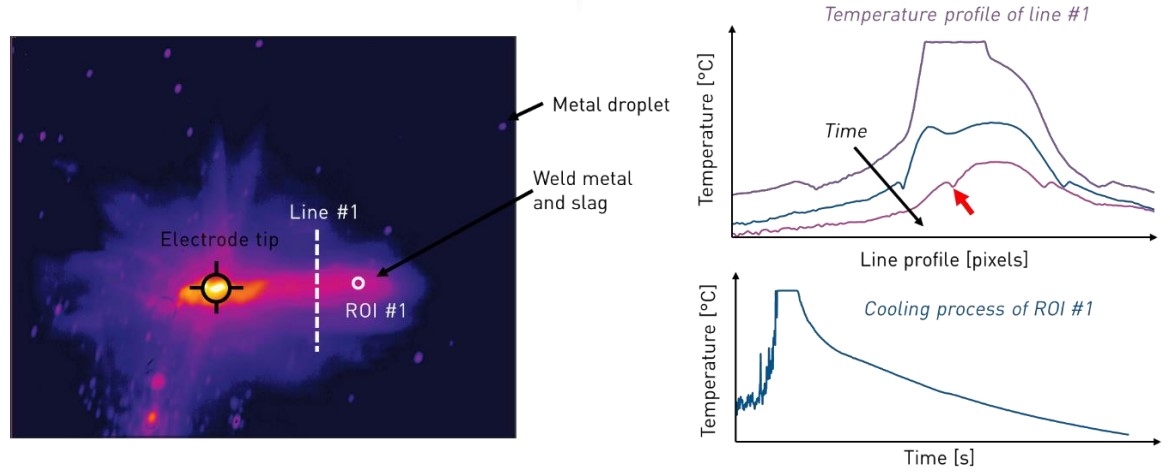

Images were processed to study the temperature profile of the metal during the welding and to assess the uniformity of the cooling. On this data, the presence of a “gutter” defect can be noted on the weld (highlighted by a red arrow below). This type of defect results from an excessive heating of the metal relatively to its thickness.

Snapshot during the manual metal arc welding process and monitoring of the weld temperature profiles.

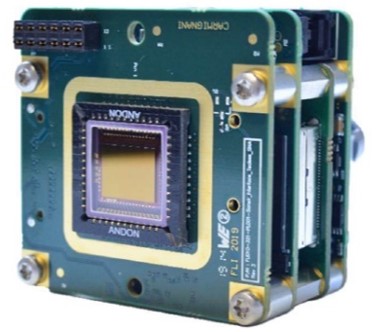

In the C-RED 3 camera, all the cooling system has been removed and the electronics squeezed to give a very small and compact high-speed SWIR camera. Below is an insight into its advantages for welding process imaging.

C-RED 3 camera.

C-RED 3 is a plug-and-play camera.

Our C-RED range of cameras offers specific features to adjust to your use case.

Additive manufacturing processes enable to build up 3D parts by depositing layers of material. When the material used is metal, monitoring the weld pool region is of particular interest to guarantee the homogeneity of the final piece as well as its robustness to mechanical stress.

C-RED 3 is a high performance camera designed for high flux short wave infrared applications (900 – 1700 nm). It is the perfect tool for research purposes and for high end industrial process monitoring. The camera can reach 600 FPS in full frame, enabling the capture of high-speed events.

C-RED 3 camera can be used to image the welding process with high spatial and temporal resolution, hence enabling an optimization of the parameters of the deposition process. We illustrated the use of C-RED 3 in a Wire Arc Additive Manufacturing (WAAM) research experiment and in a Manual Metal Arc Welding (MMAW) industrial experiment.

C-RED 3 OEM camera

C-RED 3 is very flexible and can be used for all your applications, ranging from Free Space Optics (FSO) to temperature monitoring in harsh environments.

C-RED 3 is also available as an OEM module for easy integration.

Date: November 2021

Author: Cecile Brun

Category: Application Note