Resources

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

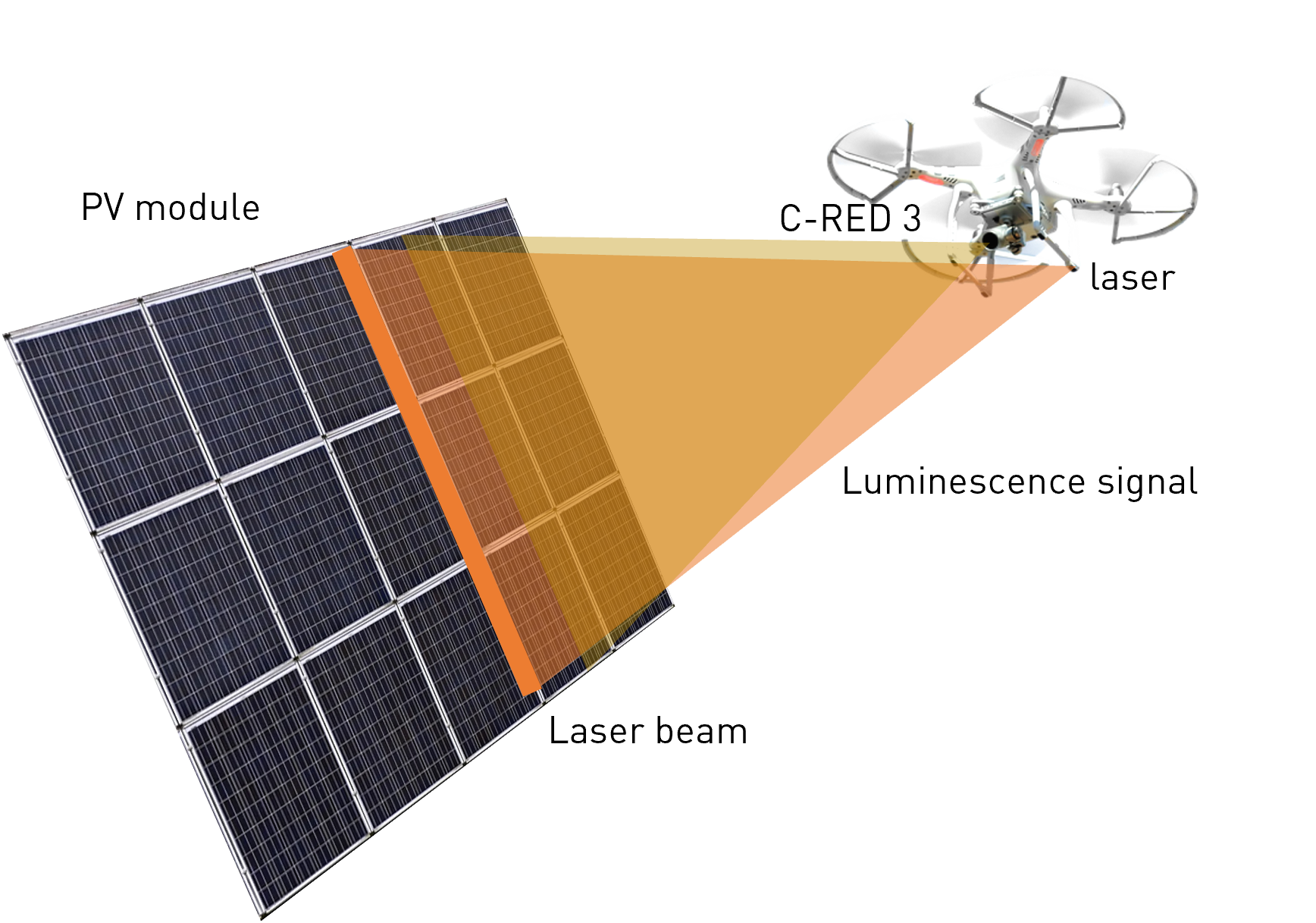

First Light Imaging, along with Creative Sight™, Optoprim, and the Technical University of Denmark (DTU), has developed an innovative drone-based solution for fast and accurate inspection of photovoltaic plants in operation called LIPI (Laser Induced Photoluminescence Imaging). The project brings the luminescence imaging technology onto a drone and into the field.

Detecting early stage failures and degradations, defects and faults, such as cracks, broken cells interconnections, shunts, etc., is critical for the operation of solar cell farms. Luminescence has been established as a highly suitable technique to characterize silicon in the context of Photovoltaic (PV) modules and wafers(1). Two methods can be used: Electroluminescence (EL)(2) and photoluminescence (PL)(3). Widely adopted, these techniques are routinely used in R&D process monitoring and industrial control.

When an alternating current is applied to a semiconductor, light is generated. This is called electroluminescence. Photovoltaic panels are made up of silicon and have a luminescence emission peak at 1150 nm. It has been shown that the light emission is directly linked to relevant physical quantities (carrier density, diode voltage, etc.).

The emission can be sensed using an external detector and spatially resolved images of photovoltaic panel modules can be obtained using this approach. Because of the emission wavelength, SWIR cameras are most adapted to this application.

However, the technique requires electrical contact and an external power supply. Hence, in the production process, it involves that the PV cell is complete. Moreover, it also involves dismantling the PV system in case of preventive maintenance.

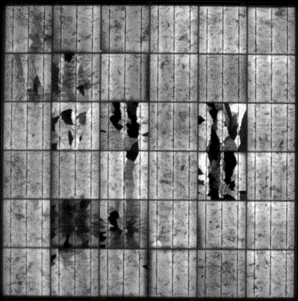

Electroluminescence image acquired using a C-RED 3 camera.

Photoluminescence imaging uses optical excitation, for example with a laser. The key advantages over electroluminescence are that the technique can be applied to a wider range of samples, such as partially processed wafer, and that it avoids contact with the sample(5). Similarly to EL, the images highlight cracks and areas of potential failure.

Take-home message

Electroluminescence and photoluminescence signals can be used to identify defects on semiconductor materials and in particular on photovoltaic modules.

Photoluminescence has the advantage of being contactless.

As a fast, safe, accurate and cost-effective solution, the inspection of photovoltaic modules with luminescence imaging is the future and a drone-based solution will bring revolutionary change to the photovoltaic industry. The technology can scale up the inspection process and enable the monitoring of large solar panel fields.

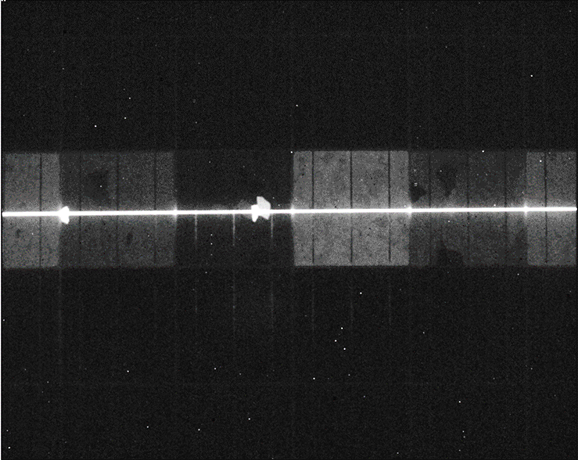

A laser is shaped into a line beam which excites the cells of the solar panel, which in turn remit light. The C-RED 3 camera combined to a SWIR-optimized objective lens is used to image the photoluminescence signal. By scanning the laser and SWIR camera over the PV panels high resolution images can be obtained, as illustrated on the adjacent image.

The system is completely contactless and will reveal microcracks and faults even before they become critical to energy production.

Photoluminescence image acquired with a C-RED 3 camera. Excitation is made with a horizontal laser line.

The laser and camera, both weight and size optimized, can be integrated in typically two types of system : hand-held and drone-embedded (4).

A high precision GPS, added to the payload, makes it a fully standalone unit that needs no meta data from the drone flight controller and can thereby be mounted on any drone.

The C-RED 3 camera is able to capture full frame (640 x 512 pixels) images at 600 frames per second, enabling high speed scanning of the photovoltaic panels.

Schematic of the full LIPI system in operation.

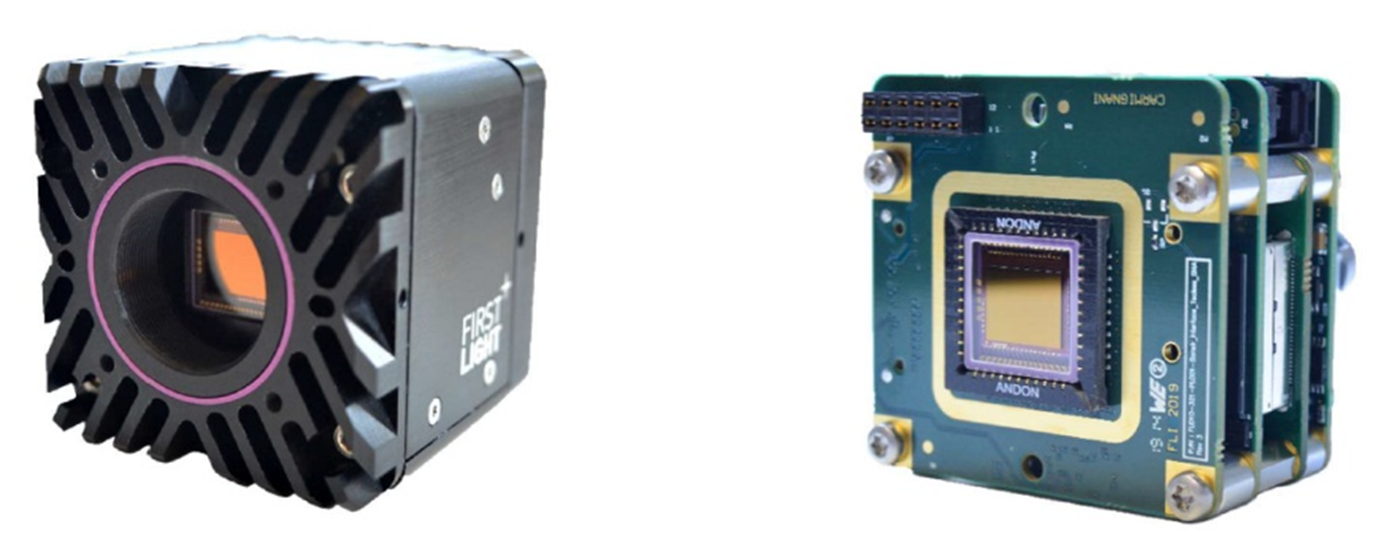

Designed specifically to address the industry market and benefiting from the expertise gained on high end scientific cameras, First Light Imaging’s C-RED 3 offers numerous assets for photovoltaic inspection.

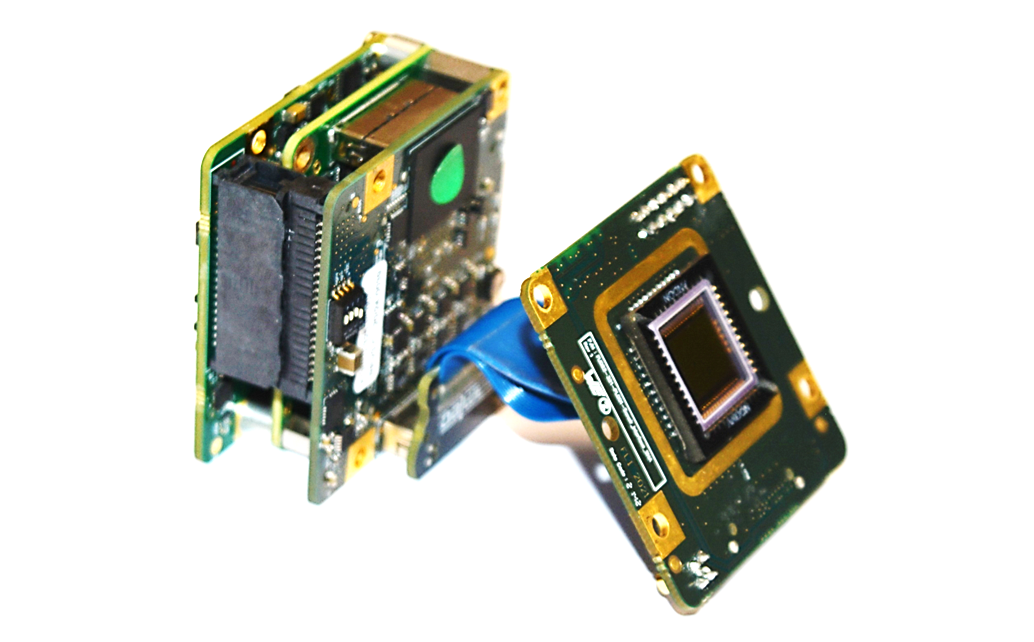

C-RED 3 camera in housed (left) and OEM (right) formats

In the C-RED 3 camera, all the cooling system has been removed and the electronics squeezed to give a very compact high-speed SWIR camera.

Below is an insight into its advantages.

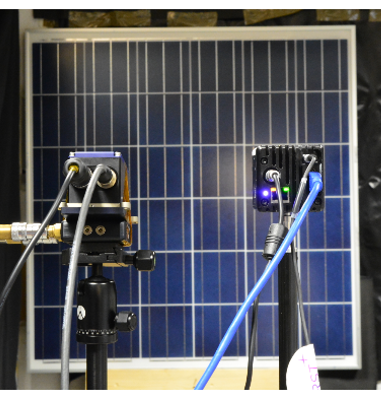

Laboratory set-up using a C-RED 3 camera (right) and a laser module (left) for photoluminescence imaging of a PV panel

C-RED 3 is a plug-and-play SWIR camera.

Our C-RED range of cameras offers hardware optimization to adjust to your specific use case.

The C-RED 3 camera also exists in OEM (without housing) format and can be customized according to your need. First Light Imaging has worked with multiple customers over the years to help integrate C-RED 3 into their systems and products. Please contact us to discuss your requirements!

Example of a C-RED 3 camera in a custom design

C-RED 3 OEM can be customized to meet your unique requirements.

To match the exact needs of your application, the C-RED 3 camera can be customized to offer a tailored long-term solution to your product.

Electroluminescence and photoluminescence are the two main imaging techniques to check the status of solar panel photovoltaic cells. In both cases the luminescence signal is in the short wave infra-red range, requiring a SWIR camera to be detected and imaged. First Light Imaging, along with Creative Sight™, Optoprim, and the Technical University of Denmark (DTU), has developed an innovative drone-based solution for fast and accurate inspection of photovoltaic plants in operation called LIPI (Laser Induced Photoluminescence Imaging). The project brings the luminescence imaging technology onto a drone and into the field.

The C-RED 3 camera, integrated in the LIPI drone solution, is an industrial-grade SWIR camera designed for high-end machine vision applications. It enables very high-speed high-quality imaging (up to 600 fps in full frame) and gives its best performances at short exposure times.

And as we want our customers to always stay one step ahead in their own market, C-RED 3 is available in OEM version to speed up custom developments and mechanical integration.

Date: March 2023

Author: Cecile Brun

Category: Application Note