Resources

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Numerous applications of Short Wave Infra-Red (SWIR) imaging require short exposure times, typically below 10 ms. Cooled SWIR cameras are over optimized for these applications cases. C-RED 3 is an uncooled, compact, and cost-optimized VGA (640x512) InGaAs camera which offers high imaging performances for short exposure time imaging. C-RED 3 opens new opportunities for industrial and scientific applications.

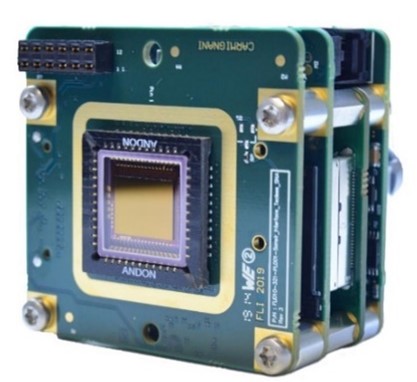

C-RED 3 is an uncooled camera based on the TECless SNAKE detector from LYNRED. The wager of an uncooled approach was made to offer the best compromise in terms of performance, compactness, and cost-effectiveness.

The first camera developed by First Light Imaging was OCAM2, a fast and low noise camera specifically designed for wavefront sensing applications in the visible range. But astronomers were frustrated not being able to use the infrared spectrum… where sky coverage is more important and stars brighter. The C-RED One camera, based on e- APD technology, was developed as the SWIR counterpart of the OCAM2. However, this camera is rather bulky and targets ultra-high performance applications. The legacy of the C-RED One camera was transferred to the InGaAs technology, giving the C-RED 2 camera. This high speed, low noise cooled camera targets intermediate performance applications, such as low order wavefront sensing. However, in applications when signal level is high there is not necessarily any need for cooling. This leads to the C-RED 3 camera where all the cooling system has been removed and electronics squeezed to give a very small high-speed SWIR camera suited for applications requiring SWaP optimized cameras. Dimensions are reduced to 55 x 55 x 60 mm.

The main characteristics of C-RED 3 are summed up in the table on the left. You can refer to the camera datasheet for more information.

C-RED 3 has been designed to be versatile and easy to integrate, it offers:

C-RED 3 can be controlled via the First Light Vision software. Alternatively, a Software Development Kit (SDK) is available to help you integrate C-RED 3 in your own environment.

| Test Measurement | Result | Unit |

| Maximum speed (full frame) | 602 | FPS |

| Mean dark + readout noise at 600 FPS | < 50 | e- |

| Quantization | 14 | Bit |

| Quantum effiency (0.9 to 1.7 µm) | > 70 | % |

| Operability | > 99.7 | % |

| Full well capacity at low gain, 600 FPS | 1400 | ke- |

| Full well capacity at high gain, 600 FPS | 33 | ke- |

| Maximum soeed 32 x 4 window | 32066 | FPS |

| Maximum soeed 320 x 256 window | 1779 | FPS |

| Power consumption | 6.5 | W |

Let us try to understand when and how to use C-RED 3…

Potential users may be anxious at the idea of using an uncooled camera… Understanding the impacts of a higher working temperature on the imaging performances is the first step to adopting C-RED 3.

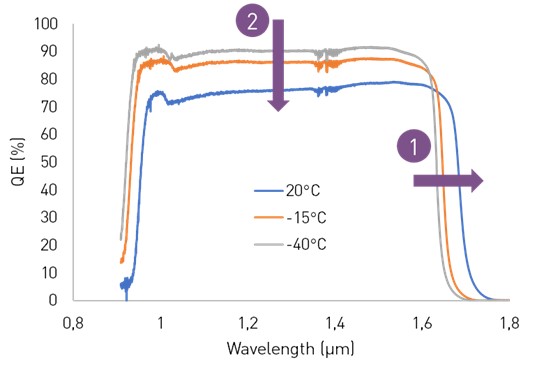

Illustrated below is the Quantum Efficiency (QE) response of InGaAs versus wavelength and operating temperature.

The quantum efficiency is both shifted (1) and reduced (2) when temperature increases:

Example: Your laser emits at 1200 nm, the QE curve shift does not affect your measurement. If the camera is at 30°C, the QE is 15% less than if the camera was cooled to 0°C. To reach an equivalent signal level, you can integrate for longer.

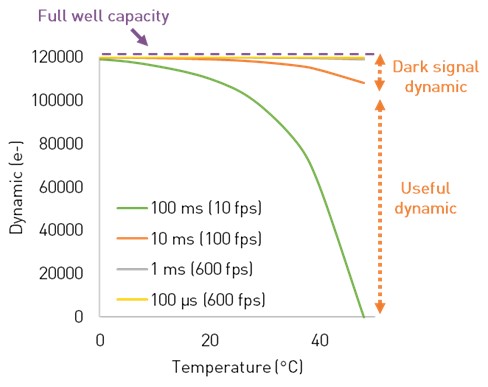

The useful dynamic is the part of the integrating capacity which is available for photons. It is limited by dark signal, caused by thermally generated electrons in the sensor.

The dark signal increases linearly with integration time and exponentially with temperature until the detector saturates.

For short integration times the dark signal is low and the useful dynamic is preserved. The figure above shows typical values in medium gain.

Example: Your application requires a 1 ms integration time and medium gain mode. The room temperature is elevated, the camera is operating at 40°C. In this case, 600 e- are thermally generated… occupying ~0.5 % of the full dynamic!

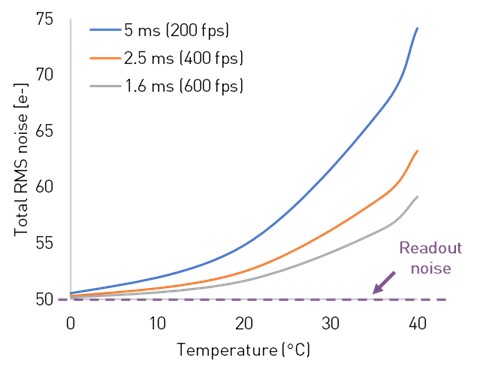

The two main noise sources linked to the detector are: dark current noise and readout noise. Dark current noise is the square root of the dark signal, hence increasing with both integration time and temperature.

The figure above illustrates that in medium gain mode for high framerates / short integration times, the total noise is kept small.

To accurately detect a signal, it must be at least 3 times higher than the dark noise.

Example: A 1300 nm laser incident on the detector provides 1014 photons⋅s-1 ⋅mm-2 (15 µW⋅mm-2 ). In medium gain and tint 1 ms, your signal represents 1014 *tint*QE*pix_size = 15⋅10 3 e-⋅pix-1 . The total dark noise is < 60 e-. Signal to noise ratio is well over 3. Your signal can easily be detected.

These considerations lead us to two questions: when does it become useful to stabilize the temperature of C-RED 3 and when does it become necessary to switch to C-RED 2 Lite (stabilized camera) or C-RED 2 (cooled camera)?

In some specific cases, stabilizing the sensor temperature may be necessary:

First Light Imaging offers the following solution:

C-RED 3 alone is not stabilized, which will result in temperature variations in time. Available with C-RED 3 is a compact water cooling adapter which can be screwed below the camera to stabilize the temperature. A passive or active water chiller must be connected to the bloc. This solution preserves compactness and cost-effectiveness.

C-RED 2 Lite is a stabilized version of the C-RED 3 camera. “Stabilized” means that the camera has the ability to maintain the sensor at a target temperature. This is done via two internal thermoelectric coolers (TEC). First Light Imaging guarantees a temperature difference of 25°C between the outer case and the sensor. Depending on how well the heat is dissipated away from the case, the sensor can be set to lower temperatures. The advantages of this solution over the C-RED 3 with a cooling plate are : higher cooling capability, guaranteed stabilization performance, and less bulkiness.

To choose between a cooled, stabilized or uncooled camera, the question you need to ask yourself is: is your acquisition limited by photon noise or dark current noise?

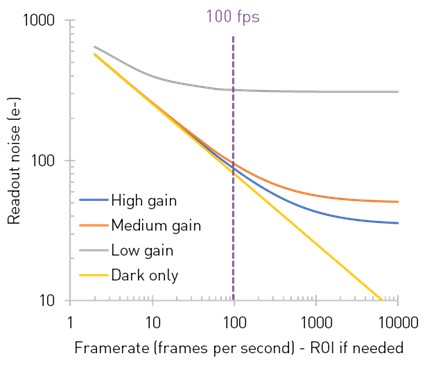

C-RED 3 readout noise versus framerate (integration time is equal to the inverse of framerate) at 35°C shows that:

Take-home message

There are three effects of temperature on a camera's performances:

However, these effects are not necessarily drawbacks.

C-RED 3 offers high performances at short integration times (below 10 ms).

You should consider regulating or cooling the sensor only for specific applications or if using long integration times.

C-RED 3 is integrated in First Light Vision, the Graphical User Interface (GUI) developed for all C-RED and C-BLUE cameras by First Light Imaging. It is compatible with both USB and CL interfaces and is cross-platform (x86 / ARM, Windows/ Linux). It is user friendly, allowing easy controlling, and offers multiple functionalities for higher end usage. To help programmers develop their own interface for C-RED 3, the Software Development Kit (SDK) provides source codes for short demos in C/C++, Labview, Python and MATLAB. C-RED 3 can also be controlled using Micro Manager.

Several on-the-fly corrections can be applied to C-RED 3 to optimize the raw data. The hardware processing developed by First Light Imaging based on the expertise acquired with the C-RED One and C-RED 2 cameras makes C-RED 3 a high performance camera.

A bad pixel map is built in the camera during the manufacturing. This map can be edited by the user to add and/or remove bad pixels.

Dark Signal Non Uniformity (DSNU) is one source of pattern noise. It results from an offset (bias) resulting from electronic disparity, and dark current. DSNU correction is usually fixed by subtracting a dark frame from the useful image.

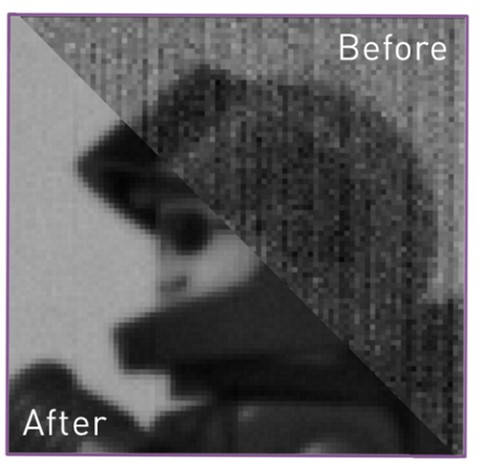

The after/ before illustrates the effect of bias correction on a raw image.

Lego® figurine acquired with a C-RED 3 operating at 40°C, in low gain, at 600 fps (tint 1.6 ms).

Fixed Pattern Non Uniformity (FPNU) is caused by inhomogeneities of pixel gain values (their ability to convert photons to electrons). It can be corrected by dividing the image by a flat frame.

Dark current level depends on temperature and integration time. Hence, with a non-stabilized camera, temperature variations in time cause fluctuations in the dark current level. In other words, to make an optimal bias/ dark correction the user has to re-build the bias frame regularly. This is often not acceptable experimentally

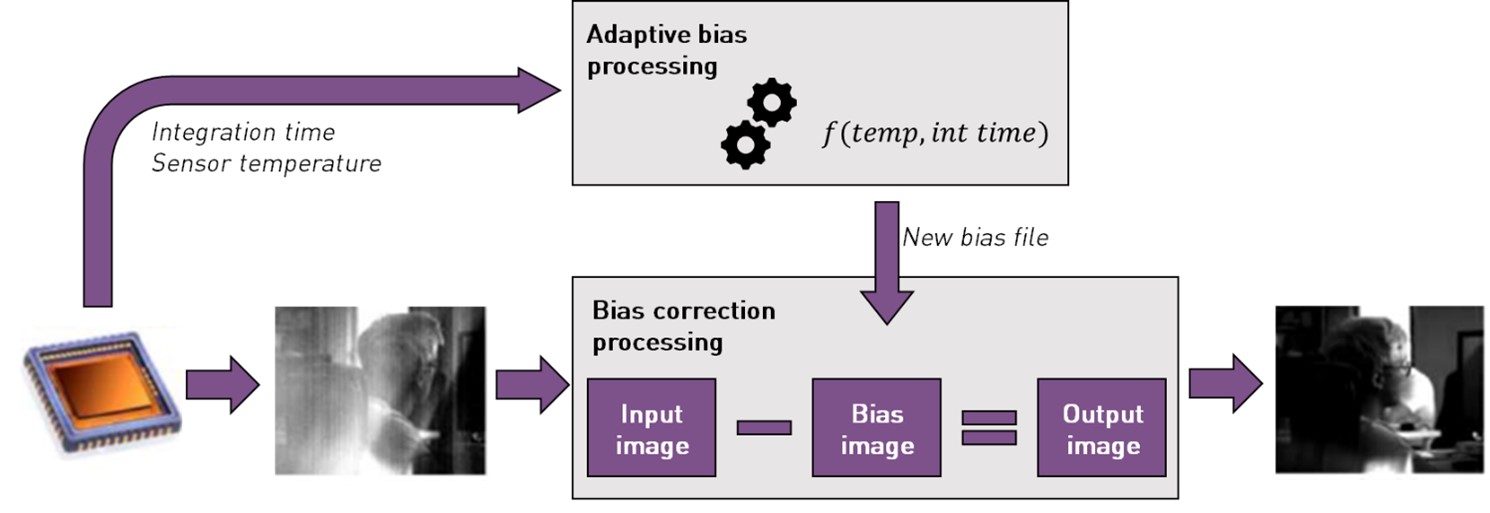

The idea of adaptive bias is to be able to apply an acceptable bias all the time, without manually re-building it when temperature fluctuates. To achieve this, First Light Imaging developed a modeling theory based on the expected physical behavior of the sensor. The bias frame is re-built every time the temperature changes 1°C or integration time is modified. C-RED 3 is entirely autonomous on building a bias frame and subtracting it on-the-fly.

Schematic illustration of the on-the-fly adaptive bias process. The bias frame computation is achieved directly in the camera, based on integration time and sensor temperature. The synthetic bias frame can then be subtracted on-the-fly

The applications of C-RED 3 are numerous and range from industry to research. We will only highlight some of them, in which First Light Imaging has already demonstrated the effectiveness of C-RED 3.

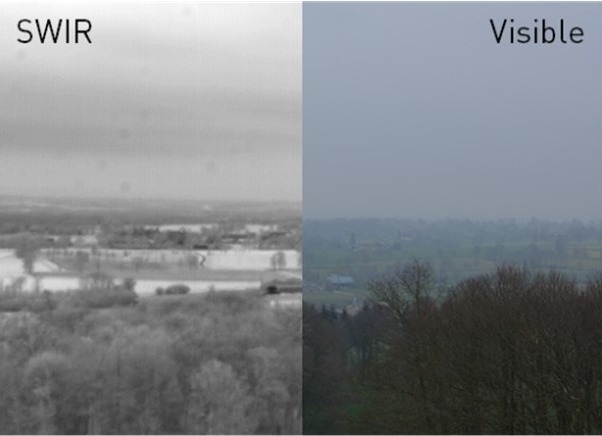

Visible and SWIR images of a foggy countryside. For SWIR imaging, a non-stabilized C-RED 3 camera combined to a SWIR 16 mm lens is used.

Free Space Optics (FSO) and Free Space Optical communication: C-RED 3 was initially developed to answer a specific need for FSO applications. You can refer to C-RED 3: a SWIR camera for FSO application 1 for more details

Laser beam profiling & laser alignment: Typically for laser-related applications, the flux levels are high. C-RED 3 perfectly answers the need for compact cameras to study power distribution and alignments of laser beams.

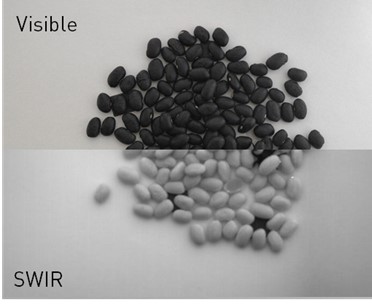

Volume industrial & high performance machine vision: For quality and production control, waste sorting, non-destructive testing… For example, in food sorting, parasite objects such as plastics or rocks are visible. For more information read our articles on hyperspectral imaging and weld monitoring.

Visible and SWIR images of black beans with parasite objects. For SWIR imaging, a non-stabilized C-RED 3 camera combined to a SWIR 16 mm lens is used. Integration time is 10 ms (100 fps) in low gain.

Surveillance and security: The low size, weight and power consumption (SWaP) of C-RED 3 opens the possibility to use this technology on airborne material (planes, UAVs). Remember that C-RED 3 can be controlled from a Jetson mini-computer and thanks to its low consumption, it can be powered with a battery.

A non-stabilized C-RED 3 camera combined to a 70-200 mm tele-objective is used for a surveillance application.

And more: In some applications SWIR is key to enable seeing the invisible. For example, in art work studies the initial carbon drawing of the artist can be seen below the paint.

Other applications include: counterfeit detection, thermography, solar panel inspection, etc.

Visible and SWIR images of a water-based painting over a pencil drawing on paper. For SWIR imaging a non-stabilized C-RED 3 camera combined to a SWIR 16 mm lens is used. Integration time is 20 ms (50 fps) in low gain.

C-RED 3 is a low SWaP camera designed for high flux short wave infrared applications. Compared to similar cameras, C-RED 3 is the fastest of its kind and runs at 600 FPS in full frame. The absence of cooling system makes it one of the most compact high-performance SWIR cameras available on the market.

Initially designed to answer a specific need of the Free Space Optics community, with C-RED 3 First Light Imaging made the wager of an uncooled approach. With its outstanding performances in terms of speed, readout noise and its low SWaP, we have witnessed it becoming a tool not only for FSO but also for new applications for airborne material and industrial vision. C-RED 3 has also been used for proof of concept applications, demonstrating the numerous advantages of SWIR imaging.

The compactness yet high performances of C-RED 3 makes it a very flexible camera which can be used for all your applications, ranging from astronomy to industrial vision.

The camera exists also in OEM version without housing and with custom features if needed. C-RED 3 weights 230 g in standard version and 100 g in OEM version

Gach, J.-L.; Boutolleau, D.; Brun, C.; Carmignani, T.; Clop, F.; Feautrier, P.; Lemarchand, S.; Stadler, E.; Wanwanscappel, Y. CRED 3: A SWIR Camera for FSO Applications. In Free-Space Laser Communications XXXII; Hemmati, H., Boroson, D. M., Eds.; SPIE: San Francisco, United States, 2020; p 14. https://doi.org/10.1117/12.2545823.

Date: April 2022

Author: Cecile Brun

Category: Application Note