Resources

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Shamrock grating turret failing to initialise correctly (not coming to rest or resetting to the wrong position).

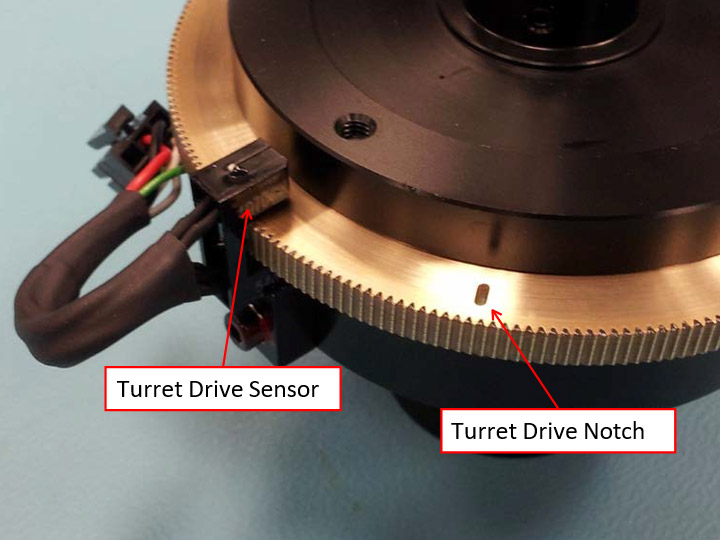

On Shamrock spectrographs which utilise a motor driven grating turret (all Shamrock Spectrographs except for the SR-163), a sensor and notch system is used to identify a mechanical zero position.

If your Shamrock is failing to initialise correctly or not finding the correct grating position, the probable reason for this is that the mechanical zero position cannot be located. Note: No error message may be shown.

There are a number of possible reasons for this:

If necessary, it may be best to remove the grating turret from the mechanical drive in order to view and gain access to the position sensor (Figure 1).

Figure 1 –Wavelength drive

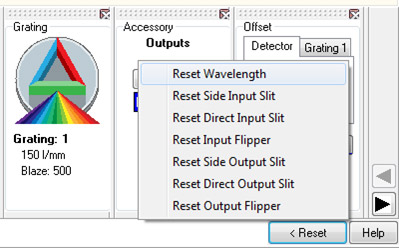

Have you performed a Wavelength Drive Reset? (Figure 2).

Figure 2 – Reset Wavelength can be selected through the Reset Button in Solis.

Action – Resetting the wavelength drive through the software will drive the grating turret to the mechanical zero position.

This will take a few moments to perform, and the wavelength drive should now be accurate, please confirm this with a known calibrated light source. If turret position is incorrect or the turret drive fails to stop at all, please continue to follow the procedure below.

Is the notch in the turret drive free from obstruction?

This may be obstructed by grease used to lubricate the turret and drive, or some type of debris (unlikely if delivery of the Shamrock was recent as the chamber is cleaned before despatch and the system has not been opened).

Note: Please note that the Shamrock should only be opened to change the grating turret, and as such, care should be taken to ensure this is performed in a clean environment to avoid dust contamination of internal components.

Action – Carefully remove any obstruction, using a pin or cotton wool bud if necessary, and clean the surrounding area with optical tissue and a small amount of methanol.

If the notch is free from obstruction, check if the sensor is loose or if it has been knocked off the turret drive. The sensor is a black plastic C-shaped component and will be noticeable if it is not in position.

Action – Please contact your local Product Support representatives for this product.

If the sensor is intact and in place?

This may indicate a possible software EEPROM issue or an electronic hardware problem.

Action – Please contact your local Product Support representatives for this product. If the turret has come to a halt, it will be possible to access to save a copy of the EEPROM through the software. Please do this and be prepared to provide this when contacting Andor.

Date: April 2022

Author: Andor Support Team

Category: Technical Article